Vertical Divider

Yet Another Replacement for ITO

Indium Tin Oxide (ITO) has proven to be a very resilient commodity for OLEDs; it’s transparent, has relatively low resistance, the right Ev to deliver electrons into emissive layers, can be fabricated easily into thin electrodes and for a smartphone the cost per panel is in the pennies range. But rare earth metal indium is predicted to run out in the next 10 years. Many start-ups offered elegant solution to ITO, using reduced resistance and lower cost as an incentive. Those companies are either bankrupt or have changed their business plan. The latest is a team led by a researcher from the University of Sydney developed a low-cost, sustainable, and readily available technology that can dim the screens of electronic devices, anti-reflection automobile mirrors, and smart architectural windows replacing one of the world’s scarcest – yet highly ubiquitous in use – modern materials: indium.

Indium Tin Oxide (ITO) has proven to be a very resilient commodity for OLEDs; it’s transparent, has relatively low resistance, the right Ev to deliver electrons into emissive layers, can be fabricated easily into thin electrodes and for a smartphone the cost per panel is in the pennies range. But rare earth metal indium is predicted to run out in the next 10 years. Many start-ups offered elegant solution to ITO, using reduced resistance and lower cost as an incentive. Those companies are either bankrupt or have changed their business plan. The latest is a team led by a researcher from the University of Sydney developed a low-cost, sustainable, and readily available technology that can dim the screens of electronic devices, anti-reflection automobile mirrors, and smart architectural windows replacing one of the world’s scarcest – yet highly ubiquitous in use – modern materials: indium.

Although small amounts are used to manufacture smart device screens, indium is expensive as it is hard to source; it naturally occurs only in small deposits. Industrial indium is often made as a byproduct of zinc mining, which means a shortage could occur if demand for optoelectronic devices – such as LCDs and touch panels – ramps up.

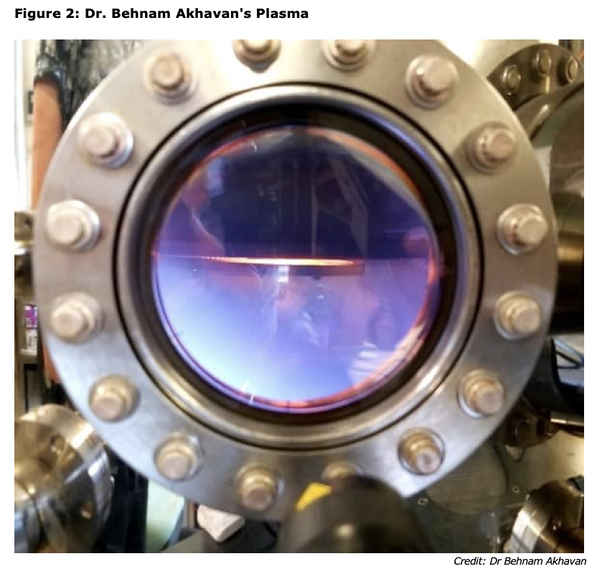

Dr Behnam Akhavan, an ARC DECRA Fellow from the School of Biomedical Engineering, School of Physics and Sydney Nano has developed a plasma-generated, hybrid nanocomposite material which is free of indium, and offers a low-cost, accessible, and environmentally sound electrochromic technology that allows glass to be dimmed at the push of a button or touch of a screen. The research was published in Solar Energy Materials and Solar Cells on 19 July. The plasma-generated material is composed of tungsten oxide and silver and can be applied to coat almost any solid surface, including flexible plastics. Known as the fourth state of matter, plasma is created by adding energy to gas. Plasma is used most commonly in fluorescent

Dr Behnam Akhavan, an ARC DECRA Fellow from the School of Biomedical Engineering, School of Physics and Sydney Nano has developed a plasma-generated, hybrid nanocomposite material which is free of indium, and offers a low-cost, accessible, and environmentally sound electrochromic technology that allows glass to be dimmed at the push of a button or touch of a screen. The research was published in Solar Energy Materials and Solar Cells on 19 July. The plasma-generated material is composed of tungsten oxide and silver and can be applied to coat almost any solid surface, including flexible plastics. Known as the fourth state of matter, plasma is created by adding energy to gas. Plasma is used most commonly in fluorescent

“When you change the transparency of a wearable electronic or a smart window, an electrochromic device is doing the work,” said Dr Akhavan.

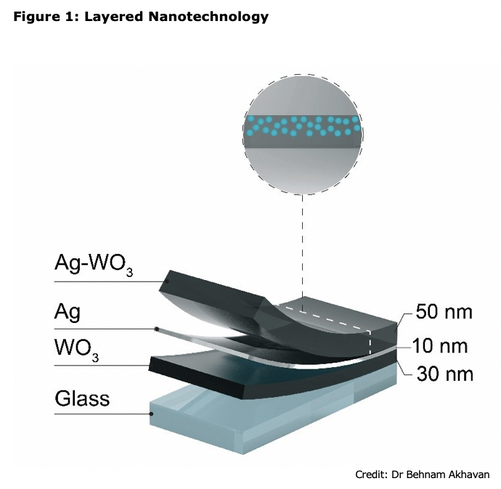

What we have created is a manufacturer’s dream: a technology that removes the need for indium and instead uses a plasma-engineered, three-layered structure that is much cheaper to produce.” Early iterations of the technology were produced for the first time in 2019, using a new method of tungsten oxide deposition known as ‘HiPIMS’ (the plasma technology used to create these materials). Now, instead of a bare tungsten oxide layer, the group has developed a nanocomposite of tungsten oxide and silver. This nanotechnology-enabled approach allows electrochromic devices to change color efficiently and rapidly upon request. The plasma coatings are transparent and also electrically conductive. They are made up of a layer of silver that is approximately 10,000 times thinner than the width of human hair, placed in between two nano-thin layers of tungsten oxide decorated with silver nanoparticles.

“These plasma-fabricated coatings can then be applied to electronic papers, smart phones and glass windows and can be dimmed with the application of a small electrical current.”

Replacing a material such as ITO in an OLED display is not a simple task as it would require complete qualification, which is an expensive and time consuming process, for which panel makers have not found to be justified on a cost basis. But if the world runs out of indium, they would be forced to use a different TCO material.

What we have created is a manufacturer’s dream: a technology that removes the need for indium and instead uses a plasma-engineered, three-layered structure that is much cheaper to produce.” Early iterations of the technology were produced for the first time in 2019, using a new method of tungsten oxide deposition known as ‘HiPIMS’ (the plasma technology used to create these materials). Now, instead of a bare tungsten oxide layer, the group has developed a nanocomposite of tungsten oxide and silver. This nanotechnology-enabled approach allows electrochromic devices to change color efficiently and rapidly upon request. The plasma coatings are transparent and also electrically conductive. They are made up of a layer of silver that is approximately 10,000 times thinner than the width of human hair, placed in between two nano-thin layers of tungsten oxide decorated with silver nanoparticles.

“These plasma-fabricated coatings can then be applied to electronic papers, smart phones and glass windows and can be dimmed with the application of a small electrical current.”

Replacing a material such as ITO in an OLED display is not a simple task as it would require complete qualification, which is an expensive and time consuming process, for which panel makers have not found to be justified on a cost basis. But if the world runs out of indium, they would be forced to use a different TCO material.

|

Contact Us

|

Barry Young

|