|

Vast Set of Components and Utilities Needed for Gen 10+ Fabs

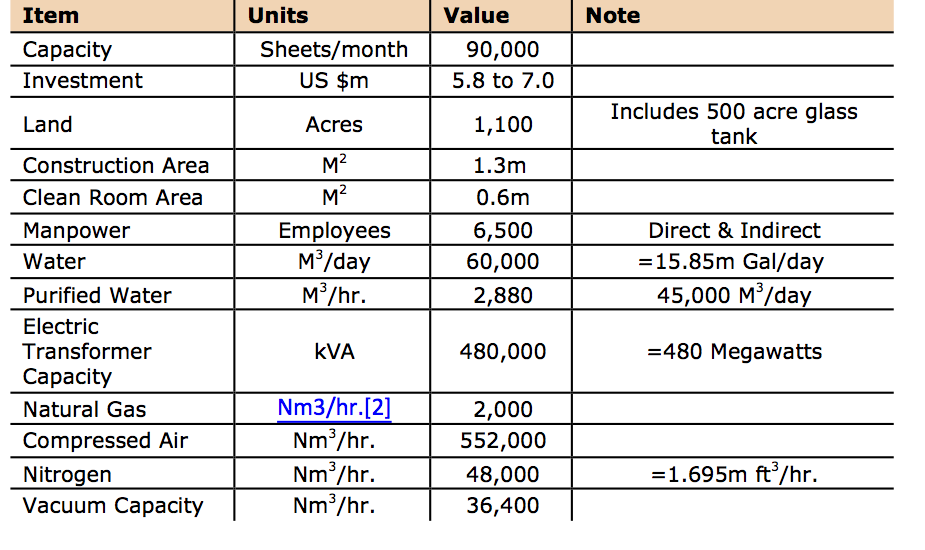

June 19, 2017 IHS has broken out a few of the key materials needed to build and run such a 10th or 11th Gen facility, showing the resources needed to the fab in operation. Aside from the investment of US$5.0b to US$7.0b, the water usage is 60,000 m3/day, a cubic meter of liquid = 264.172 gallons, or 15.85m gallons/day. If operated in Tennessee, the fab would represent 1.73% of the daily water usage of the entire state, using USGS figures from 2005. Again taking Tennessee as the home state, electricity usage of 480 Megawatts would equal .76% of the entire state’s electrical capacity, and Nitrogen, which is stored on-site and replenished almost daily, would translate to usage of 1.695m ft3/hour, and while bulk rates would be lower than $0.165/ft3, that comes to $279,675/hour at single tank rate. The Chinese press used these figures and others to argue that it is unrealistic to think that such a facility would be practical in the U.S. Table 1: Gen 10.5 Resource Requirements Source: IHS 2017

|

Vertical Divider

|

|

Contact Us

|

Barry Young

|