Vertical Divider

University Of Waterloo Develops "Paste-And-Cut" Lower Cost And

Faster Than “Pick And Place”

July 19, 2020

Researchers from the University of Waterloo in Canada developed a new transfer and bonding method to deposit a flexible microLED array on plastic substrates.

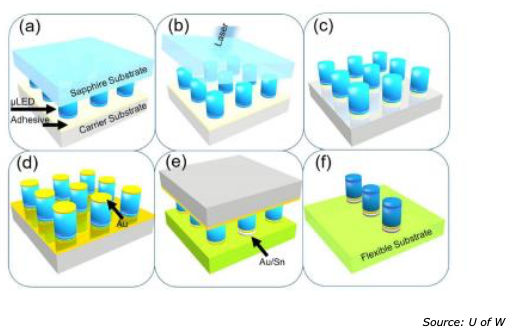

Figure 1: Paste and Cut Transfer

Faster Than “Pick And Place”

July 19, 2020

Researchers from the University of Waterloo in Canada developed a new transfer and bonding method to deposit a flexible microLED array on plastic substrates.

Figure 1: Paste and Cut Transfer

The technique, referred to as a "paste-and-cut", starts with bonding the LEDs on a process/handle wafer are temporarily bonded (pasted) onto a glass substrate and are then released (cut) to the flexible substrate. This approach allows the LED to be optimized and then combined with other materials. The use of a metal bonding layer enhances the electrical and thermal conductivity of the diode structure on the flexible substrate. Plastic substrates problematic because of the electrically and thermally insulating nature of the plastic, and this simple bonding layer design approach overcomes these limitations.

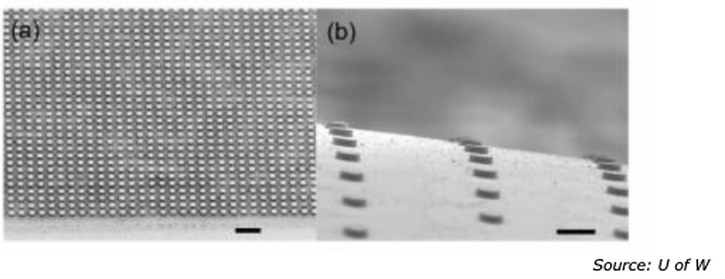

Figure 2: Results of Paste and Cut Transfer

Figure 2: Results of Paste and Cut Transfer

|

Contact Us

|

Barry Young

|