Vertical Divider

Samsung and LG Display Exiting LCD Production Faster than Expected

February 09, 2020

Samsung and LG are planning on selling a major part of their respective production line that make LCD panels. Smaller stakeholders have an opportunity to gain a greater share of the market now dominated by BOE and CSoT by buying out Gen 7 and Gen 8 fab equipment from Samsung and LG. Samsung and LG combine for $33 billion in LCD revenue or ~30%. LGD has already shifted to OLED TV panels and SDC’s $11b investment in QD-OLED signaled their intent to move away from LCDs TVs

Samsung Display has reportedly sold the LCD manufacturing equipment at its Gen-8 LCD production line to China’s Efonlong. The equipment will be shipped to China next month and Samsung will use the capacity freed up to produce quantum dot displays.

LG is looking to close a deal with another Chinese LCD display manufacturer. The South Korean brand also wishes to sell its LCD manufacturing equipment which is from its P8 manufacturing line. LG will use the new production capacity to boost OLED production in its manufacturing plants in Paju.

LG Display reported operating loss of KRW 422 billion, compared with an operating loss of KRW 436 billion in the third quarter of 2019 and the operating profit of KRW 279 billion in the fourth quarter of 2018. EBITDA of LG Display in the fourth quarter of 2019 was KRW 586 billion, compared with EBITDA of KRW 613 billion in the third quarter of 2019 and with EBITDA of KRW 1,134 billion in the fourth quarter of 2018.

LG Display posted net loss of KRW 1,817 billion in Q4, compared with the net loss of KRW 442 billion in the third quarter of 2019 and the net income of KRW 153 billion in the fourth quarter of 2018.The revenue increase of 10 percent quarter-on-quarter was driven by a rise in sales of large-size OLED panels for TVs and P-OLED (Plastic OLED) panels for smartphones which also resulted in an 18 percent increase of ASP compared to the previous quarter. LG Display achieved a rise in P-OLED shipments, as it improved the TFE process in one Gen 6 fab in the fourth quarter. The company’s operating loss improvement on a quarter-on-quarter basis was limited due to an increase in fixed costs for full-scale P-OLED mass-production and additional costs for the company’s move towards structural innovation for its LCD business. The net loss was mainly due to the write-off from the OLED Lighting business and KRW 1.4 trillion won due to the underutilization of the Gen 6 due to the TFE problem in prior quarters. .

- Panels for TVs accounted for 28 percent of the revenue, 4 percent down from the previous quarter due LCD TV panels

- Panels for mobile devices accounted for 36 percent, an 8 percent quarter-on-quarter increase, driven by the shipment increase of P-OLED panels for smartphones, while those for tablets and notebook PCs accounted for 20 percent and desktop monitors for 16 percent respectively.

LG Display said. “We will make efforts to achieve a significant revenue increase in large-size OLED panels as our OLED plant (90,000 substrate/mo. capacity) in China will ramp up production, and continue to stably manage forecasts for P-OLED panels for smartphones as well as for automobiles,” Dong-hee Suh, CFO of LG Display, said.

The company has said it will halt domestic production of LCD TV panels by the end of the year and is now investing heavily in OLED displays that are generally thinner and allow more flexibility in device design than LCDs.

The off shoot of the Korean LCD fab closings is that captured component and material suppliers are finding it difficult to compete. LG Chem is the earliest supplier to announce the closing of a key component for LCD production, glass substrates, at its facility in Paju, South Korea. LG Chem announced back in 2009 that it would enter the display substrate business with an investment of $2.5b US over nine years and a partnership with Schott a German specialty glass producer. At the time they were competing with Asahi Glass, NEG and a JV between Corning (GLW) and Samsung Display, which Corning bought out Samsung’s 42.3% share in late 2013. When the initial LG Chem investment was made the company expected to produce 50m m2 of glass and generating $1.7b in sales by 2018. The business actually generates ~$40m annually.

The SDC/Corning JV remains a supplier to SDC under a 10 year contract signed in 2013, but Corning has been either taking that capacity off line or converting it to Gorilla Glass production as LCD production slowed. Local Korean press has indicated that Corning has been taking voluntary resignations as South Korean glass demand slowed and has concentrated resources for glass substrates in China to support the base of Gen 8.5/8.6 LCD fabs.

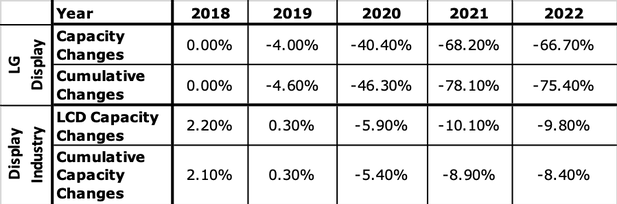

While the closings will take place in 2020, the effect, relative to previous expectations for fab ramp, would continue into 2021, with the greatest reduction in that year. If the P10 Gen 10.5 Paju fab remains on schedule, it would account for the slight decrease in the cumulative reduction and all of the decrease in 2022. Without the P10 fab, LG Display would have no large panel (TV) production capacity increase by the end of 2020. From 2019 to 2022, the cumulative reduction in LG’s TV capacity will be 75.4%, which will reduce the industry’s LCD TV capacity by 8.4%

Table 1: LG/Industry Effect of LCD TV Fab Closing

Source: SCMR LLC, Company Data

|

Contact Us

|

Barry Young

|