Vertical Divider

|

Quantum Dots Haven’t Saved LCD TVs, Maybe Micro LEDs Will Save Quantum Dots

October 10, 2017 There have been reports out of Korea that Samsung is disappointed with the sales results of their highly publicized QLED TVs and as we discussed previously, they came out with a stripped down lower cost Q6 model. Apparently, if buyers are flush with enough cash to buy the best TV, they are picking OLEDs. Moreover, the plans to shift from a QD film to a QD color filter have come up against a number of obstacles. The main issue being any external light converted by the color filter and messes up the image. Trying to add yet another polarizer has the effect of adding cost, thickness and may even cause mura. So the QD industry is looking for other markets. Micro LEDs are one of the hottest topics in the display industry and we have been covering it for months. The technology enthusiasts claim that it will challenge OLEDs for supremacy in the US$150b display market and big acquisitions by some of the top brands in consumer electronics have led to lots of speculation about when this technology will reach the market. One of the biggest unanswered questions for Micro LEDs is whether or not the technology can be manufactured efficiently and at scale due to the currently unsolved problem of mass transfer of LEDs from a sapphire backplane in a format of all LEDs to a glass or plastic substrate with a pixelated format. Manufacturing RGB Micro LED displays requires a complex process, which tends to cause a high defect rate, driving up costs and increasing time to market. Nanosys, a major purveyor of quantum dots, believes they have the answer. Dr. Zhong Sheng Luo, Nanosys Director of Applications Engineering, believes that by using Quantum Dot color converters for Micro LED displays He outlines two ways to manufacture Micro LED displays: the heterogeneous approach or the monolithic approach:

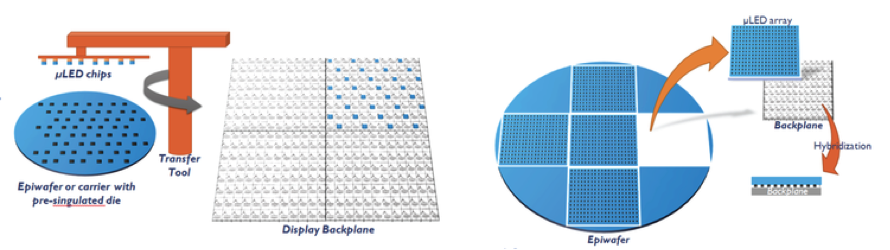

Either approach has proven to be quite challenging to achieve good yields across all three colors over the millions of RGB pixels required by today’s high-resolution displays. Pick and place manufacturing requires high precision over an incredible number of operations, where the tiniest of errors can lead to dead pixels. The monolithic approach suffers from the challenge of manufacturing three different colors of LED on the same substrate. Each color LED requires different manufacturing process conditions. Combining three together leads to poor uniformity and compromised performance. Figure 1: Heterogeneous Integration (Left) and Monolithic Integration (Right) Source: Yole Dévelopment

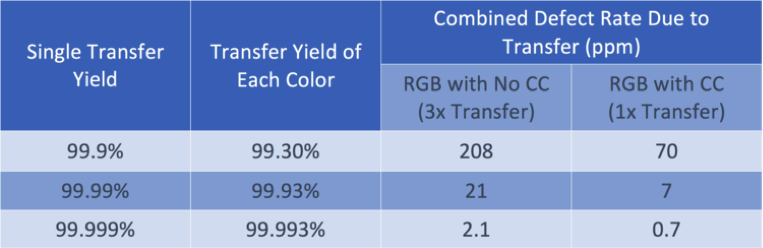

Dr. Luo, believes Quantum Dot’ color converters can solve the problem. Instead of mixing red, blue and green LED chips, Quantum Dots can be applied to a single color blue microLED array that is much simpler to make. Patterned, photo-emissive quantum dots can then convert blue light into both red and green at the appropriate sub pixel locations. Quantum dots are tunable and compatible with the Micro LED manufacturing process. Quantum Dot color converters can also simplify the electrical driving system for the display. Quantum Dot color converters can reduce the defect rate that is associated with pick and place manufacturing. Below is an example showing that the combined transfer defect rate for an AR/VR display can be improved by 3X by using a Quantum Dot color conversion solution. Figure 2: Transfer Yields and Rate Source: Yole Dévelopment

Assumptions: 4” diagonal, 450PPI, ~1.4M pixels or ~4.2M sub pixels, 200k spread sub pixel or 600k continuous pixels per transfer (constant transfer area). The productivity is also improved by 3x with color conversion solution. What Nanosys seems to demonstrate is that the various Pick and Place processes are to error prone to work, independent of the overall TACT, which is in some cases hours. However, what Dr. Luo fails to mention is the yield of individual LEDs as well as the catastrophic failures, which many involved in the Micro LED research believe that a certain level redundancy is required. We still believe that Micro LEDs are promising but their remains much work left, with no simple solutions. |

|

|

Contact Us

|

Barry Young

|