Vertical Divider

|

OLEDWorks Takes on Leadership of OLED Lighting; DOE Reports Progress but Challenges

April 22, 2019 With the demise of LG Display OLED lighting initiative, the OLED lighting industry is refocusing, leaving OLEDWorks in a unique, advantageous position. The company is now leading the industry and will receive a new level of scrutiny. John Holland, the company’s Chief Revenue Officer said, “Recently, we’ve had a number of new customers from North America, Asia, and Europe because they want to continue to design and sell OLED fixtures,” says at OLEDWorks. “We couldn’t be happier about the opportunity to build these new relationships and increase the amount of commercially available OLED lighting options in the market. However. the US Department of Energy (DOE) announced results of its ongoing research testing OLED SSL technology with a focus on general illumination applications. In a new “round 2” report based on accelerated stress testing of OLED panels, the researchers found improvement in the latest products, yet longevity still trails LED significantly. The report also includes an analysis of the new OLEDWorks Brite 3 panel after 1500 hours of testing. While OLED panels offer product developers freedom of form, manufacturing costs along with performance and reliability issues have limited OLED technology to niche uses in lighting. |

|

Meanwhile, DOE reports that planar edge-lit LED products are increasingly popular and able to offer some of the same benefits as OLED. DOE has continued to support OLED research and fund projects that utilize the technology, believing that maturity would bring OLED nearer to LEDs in performance and reliability. Currently, the DOE is struggling with funding with the Trump administration having less of a focus on energy efficiency. But the agency still has continuing research, and OLED stress testing is one area where such work continues. The latest report seems to lie somewhere between a Gateway and a Caliper report with elements of each because some of the data presented is from field deployments like Gateway and other parts of the data are based on lab testing like Caliper.

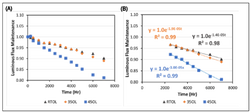

Table 1: Average Luminous Flux Maintenance for OLEDWorks Brite 2 (A) and exponential fits of the latter part of the data (B).

Table 1: Average Luminous Flux Maintenance for OLEDWorks Brite 2 (A) and exponential fits of the latter part of the data (B).

Source:US Department of Energy .

The researchers have been continuously operating populations of a number of panels from multiple manufacturers at slightly elevated ambient temperatures of 35°C or 45°C with test duration now up to 7000 hours. Moreover, the team has begun a more accelerated test of the relatively new Brite 3 panels from OLEDWorks, testing at 90°C and 90% humidity, and exposing the panels to power cycling. In each case, there is parallel operation of populations of the same products at normal conditions, with all of the Brite 3 tests lasting 1500 hours. On the surface, the results look positive. Researchers have tested older OLEDWorks Brite 2 panels for 7000 hours in three stress protocols. Output flux maintenance remains above 85% in all cases. The researchers report the largest decline in output during the first 2000 hours, followed by a leveling off and then a predictable decline on a moderate scale. Moreover, chromaticity shift is much better in the more recent products that have been tested.

However, DOE pointed out that the performance after stress testing is poorer than some mid-power LEDs that were manufactured in 2011. And back in that timeframe, mid-power LEDs were not known for good performance over time or tough conditions as we documented. As for the newest product tested, the Brite 3 panels achieved flux maintenance greater than 92% even with the exposure to a tougher operating environment. The researchers noted the escalated stress and the results indicate that OLEDWorks has improved its encapsulation technology. There was also very little chromaticity shift after 1500 hours. The DOE remains a proponent of OLED technology serving as a complement to LED technology and suggests that the latest test results support that vision. Moreover, the researchers are now confident that the accelerated stress mechanisms are well understood and can be modeled using standard SSL industry methodologies such as a single-exponential decay function following an initial period of declining performance.

Full details of the stress protocols and testing methodologies are available in the DOE report.

However, DOE pointed out that the performance after stress testing is poorer than some mid-power LEDs that were manufactured in 2011. And back in that timeframe, mid-power LEDs were not known for good performance over time or tough conditions as we documented. As for the newest product tested, the Brite 3 panels achieved flux maintenance greater than 92% even with the exposure to a tougher operating environment. The researchers noted the escalated stress and the results indicate that OLEDWorks has improved its encapsulation technology. There was also very little chromaticity shift after 1500 hours. The DOE remains a proponent of OLED technology serving as a complement to LED technology and suggests that the latest test results support that vision. Moreover, the researchers are now confident that the accelerated stress mechanisms are well understood and can be modeled using standard SSL industry methodologies such as a single-exponential decay function following an initial period of declining performance.

Full details of the stress protocols and testing methodologies are available in the DOE report.

|

Contact Us

|

Barry Young

|