Vertical Divider

Nanostructures Improve OLED Efficiency

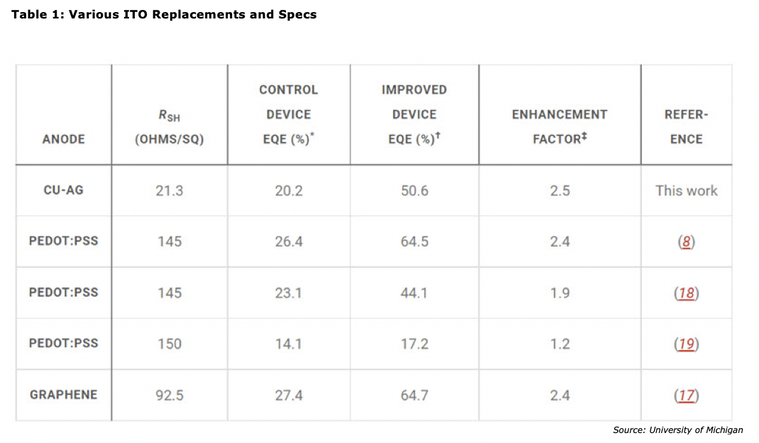

One of the key challenges in getting light out of the OLED is Total Internal Reflection (TIR) - the phenomenon that is exploited in optical fibers. Light can be trapped inside transparent substrates, bouncing between the surfaces of the different materials that are around the layer containing the light. There are three areas that cause light to be lost and a group at the University of Michigan have focused on one of these, the losses caused by the light in the OLED stack trapped by the OLED stack and the transparent conducting electrode on the top of the device. The researchers detail different approaches to solving the problem by replacing the ITO with carbon-based materials, such as graphene, conductive polymers, and optimized PEDOT:PSS/Titanium Oxide and graphene. However, all of these solutions involve significant and difficult processing.

One of the key challenges in getting light out of the OLED is Total Internal Reflection (TIR) - the phenomenon that is exploited in optical fibers. Light can be trapped inside transparent substrates, bouncing between the surfaces of the different materials that are around the layer containing the light. There are three areas that cause light to be lost and a group at the University of Michigan have focused on one of these, the losses caused by the light in the OLED stack trapped by the OLED stack and the transparent conducting electrode on the top of the device. The researchers detail different approaches to solving the problem by replacing the ITO with carbon-based materials, such as graphene, conductive polymers, and optimized PEDOT:PSS/Titanium Oxide and graphene. However, all of these solutions involve significant and difficult processing.

Research showed that by replacing the ITO layer with two very thin layers - 5 nanometers of silver on top of a copper seed layer - the waveguide loss is eliminated completely. The key is that these layers can be deposited using the same vacuum chambers that are already used in OLED manufacture to deposit other layers, so it is relatively simple to introduce in industrial production.

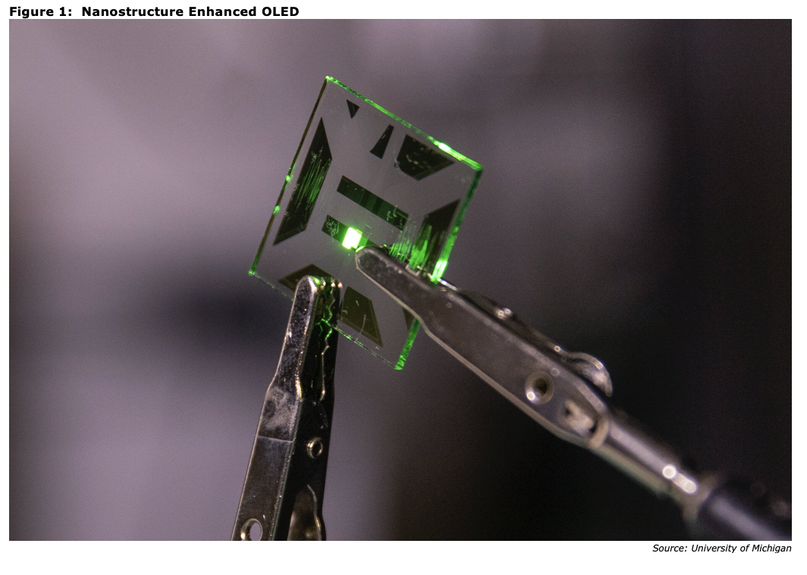

“Industry may be able to liberate more than 40% of the light, in part by trading the conventional indium tin oxide electrodes for our nanoscale layer of transparent silver,” said Changyeong Jeong, first author and a Ph.D. candidate in electrical and computer engineering. The group used an index-matched outcoupling layer to eliminate light trapping in the glass on the OLED and when this was implemented, the edges of the glass were almost completely dark, and the light emitted was about 20% brighter. L. Jay Guo of the Michigan group formed a company based in Beijing, Zenithnano Technology, in 2018 to exploit the discovery and develop his lab’s inventions of transparent, flexible metal electrodes for displays and touchscreens. The University of Michigan has filed for patent protection. (BR)

SCIENCE ADVANCES•25 Jun 2021•Vol 7, Issue 26•DOI: 10.1126/sciadv.abg0355

“Industry may be able to liberate more than 40% of the light, in part by trading the conventional indium tin oxide electrodes for our nanoscale layer of transparent silver,” said Changyeong Jeong, first author and a Ph.D. candidate in electrical and computer engineering. The group used an index-matched outcoupling layer to eliminate light trapping in the glass on the OLED and when this was implemented, the edges of the glass were almost completely dark, and the light emitted was about 20% brighter. L. Jay Guo of the Michigan group formed a company based in Beijing, Zenithnano Technology, in 2018 to exploit the discovery and develop his lab’s inventions of transparent, flexible metal electrodes for displays and touchscreens. The University of Michigan has filed for patent protection. (BR)

SCIENCE ADVANCES•25 Jun 2021•Vol 7, Issue 26•DOI: 10.1126/sciadv.abg0355

|

Contact Us

|

Barry Young

|