|

Simulating Plasma Coupling Phenomenon to Improve EQE

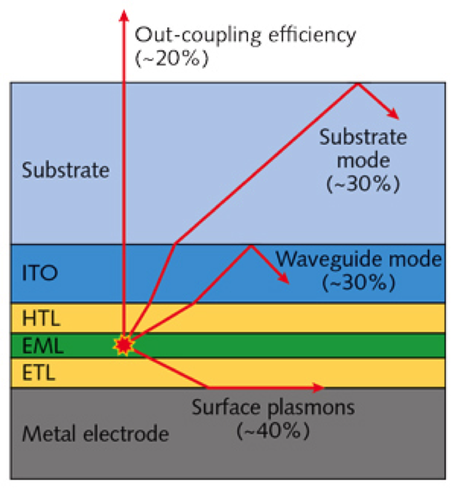

February 28, 207 Konica Minolta is one of the leaders in trying to bring OLED lighting to market and they have found that OLEDs aren't nearly as bright or as energy-efficient as their inorganic counterparts, LEDs, and so researchers are developing designs to meet growing demand. The company supports the development of cutting-edge OLED devices for imaging and optics, often working in partnership with Japan's leading universities. Researchers at the Konica Minolta Laboratory USA (San Mateo, CA), led by Leiming Wang, are using numerical simulation to analyze light-loss mechanisms in OLEDs to virtually test ways to improve designs. OLED lighting is impacted by complex plasmon coupling phenomenon that accounts for 40% of the light lost through interactions within the device. The next figure shows the layout of an OLED device, with an anode made of transparent indium tin oxide (ITO), three organic layers—a hole-transport layer (HTL), an emitting layer (EML), and an electron-transport layer (ETL)—and a silver cathode. These are all fabricated on a glass substrate, which passes light when the device is turned on. Figure 1 Schematic of a Multilayer OLED Structure Source: Comsol

When current is applied, electrons are injected at the cathode and holes at the anode. Electrons and holes travel toward each other through the layers, combining in the emissive layer to release energy in the form of photons. This happens quickly while current is flowing, causing a stream of continuous light. But some photons never make it to the outside world. Light losses in an OLED can occur through several mechanisms, such as differences in the refractive indices of each layer that can cause light to reflect within the layers rather than traveling outward as shown in the next figure. Figure 2A schematic Source: Comsol

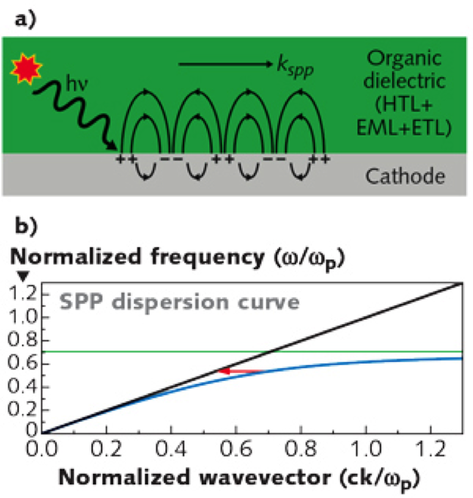

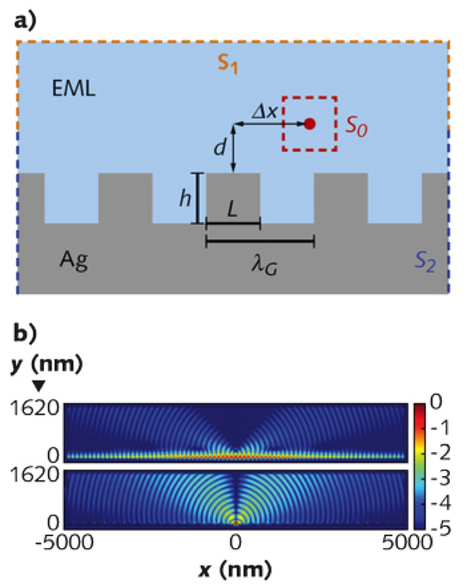

(a) shows surface plasmons coupling with dipole radiation in an OLED, catching the photons in the SPP wave rather than allowing them to be emitted through the OLED glass substrate. A plot in COMSOL software (b) shows the SPP dispersion curve. The black diagonal line represents the light line, while the green horizontal line represents the surface-plasmon frequency. The blue SPP dispersion curve approaches these asymptotically in the low- and high-frequency limit, respectively. The red arrow represents the grating Wang's team explored another mode of loss, the coupling of dipole emission with surface plasmons at the interface between the cathode and the organic material layer. Surface plasmons are waves of oscillating electrons on the surface of a conductor. In OLEDs, light emitted from radiating dipoles (molecular excitons) in the emissive layer can couple to the electron oscillations in the cathode, resulting in the presence of electromagnetic waves in the infrared or visible region of the spectrum called surface-plasmon polaritons (SPPs). These waves travel along the cathode surface as they decay, rather than permitting them to radiate through the glass (see Fig. 2a). Interest in SPPs is due to their excellent confinement of electromagnetic energy beyond the diffraction limit. As a result, they are well represented in numerous areas of near-field optics, biosensing, and metamaterials. However, in the optimization of an OLED, SPPs are a dominant loss factor. Because of the presence of the metal cathode in the close vicinity of the organic emitters, some light is absorbed by the electrons in the cathode, causing the electrons to oscillate and form the SPPs. These are eventually dissipated as heat, leading to significant energy loss. If the loss via SPPs can be reduced, the outcoupling efficiency of the OLED can be increased. SPPs propagate along surfaces—but not just any surface. SPPs are found along an interface between two materials that have a different sign in their permittivity. Many common materials, such as air, water, plastic, and paper, have a positive permittivity. Metals like gold, silver, and aluminum have a negative permittivity, and so SPPs can exist at the interface between gold and air, for example. Just because an SPP can exist at that interface, however, does not mean that it is trivial to generate and control them. Generating an SPP with a traditional light source such as a laser is slightly more complicated, as is the inverse process—converting an SPP to visible light as in an OLED. To couple freely propagating light and SPPs, their dispersion curves need to intersect, which is analogous to matching the energy and moment of the two (see Fig. 2b). The diagonal black line represents the dispersion curve for light propagating freely in air, while the blue line is the dispersion curve for an SPP at an air/metal interface. The two lines approach each other asymptotically, but they do not intersect. There are several techniques to make these two curves meet, such as using a prism in either a Kretschmann or Otto configuration. Another technique is the use of a grating. A grating has a regularly repeated pattern, like a sine wave or sawtooth pattern. The periodicity has its own wavevector, which can be added (or subtracted) to the wavevector of the SPP to allow dispersion curve matching, represented by the red arrow in the plot in Fig. 2. Implementing the grating coupling numerically is straightforward using multiphysics simulation that solves for Maxwell's equations, which means that the coupling between free-space light and SPPs is inherently accounted for without any additional modifications. Using numerical simulation in software by COMSOL (Burlington, MA), Wang modeled light emission from the EML and the SPPs present in the system to analyze ways to prevent light loss. One promising concept included a nanograting cathode structure (next figure) that disrupts the formation of the SPP mode, reducing the energy coupling between the dipole emission and the plasmons. Figure 3 A Nanograting Surface for an OLED Cathode is shown (a). Source: Comsol

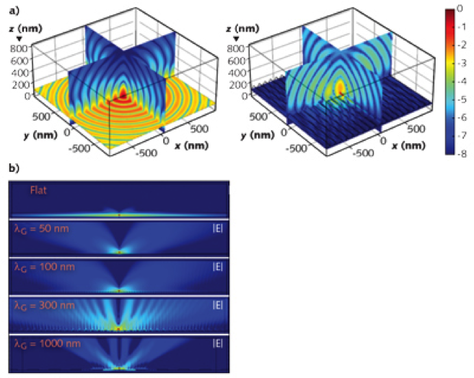

Wang's simulation team tested the effects of different pitch heights and widths to determine the optimal arrangement. (b) shows the simulated 2D field distribution of dipole emission with flat (top) and nanograting (bottom) cathode interfaces. For the flat interface, most of the emission is coupled to the SPP wave, with only a small portion radiated as free-space light (indicated by its much weaker intensity). The coupling is greatly suppressed by the nanograting structure. Figure 4 COMSOL modeling results (a) show the distribution of emission when a flat structure (left) and a nanograting (right) are used; the intensity is normalized and plotted on a log scale. Simulation results show different emission patterns resulting from several nanograting cathode designs (b). Source: Comsol

Wang's simulation results revealed the electromagnetic field distribution and the proportion of light that escaped from the OLED for different cathode shapes (see Fig. 3b). From the model results, his team was able to confirm that this phenomenon accounts for significant portions of the light lost. His team modeled the OLED with flat and nanograting cathodes, changing geometric parameters to determine the optimal configuration (see Fig. 4). They also performed a simulation to study the influence of different dipole orientations, studying the effect of the dipole position and wavelength on the level of light loss because of SPPs. They used a power-flow analysis to calculate the portion of light emitted from the EML that actually escaped the glass. Through their simulations, Wang's team determined that they could reduce the plasmon losses by 50% using the optimized nanostructure surface in the cathode. Through his simulation work, Wang was able to offer a promising new OLED design with significantly increased efficiency. The use of Multiphysics modeling software allowed the researchers to not only understand the breakdown of loss mechanisms, but to easily test the influence of different design constraints and adjust the OLEDs accordingly, allowing plasmon losses to be cut in half. Information in this article came from Sarah Fields, technical marketing engineer at COMSOL, Burlington, MA; e-mail: [email protected]. |

Vertical Divider

|

|

Contact Us

|

Barry Young

|