Vertical Divider

Kopin Develops the First All Plastic Pancake Optic for Near Eye Applications

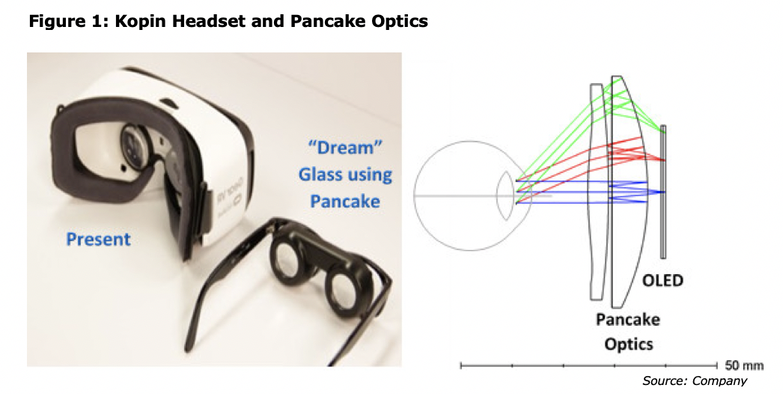

Kopin® Corporation has developed an all-plastic Pancake® optics for virtual reality (VR), augmented reality (AR) and mixed reality (MR) applications. This is a major advance and believed to be the first all-plastic Pancake optics with excellent performance. Pancake optics, compared to other optics designs, can provide a far superior magnified image quality in a much thinner form factor, especially for products with field of views (FOV) ranging from 50 degrees to 100 degrees. However, previous Pancake optics needed at least one spherical glass lens to avoid image artifacts caused by birefringence of the plastic material, but this glass lens added both weight and cost to the lens system. Kopin’s new all-plastic Pancake optics with all aspherical lenses, substantially reduces the weight and thickness while significantly improving the image quality – all at a lower cost. Pancake optics work by reflecting light back and forth within the optical system. To reflect the light correctly and avoid image artifacts, the polarization state of light must be precisely controlled. Unfortunately, plastic materials usually have large birefringence that disturbs the polarization state, and until now all-plastic lenses have not been able to overcome the disturbance of the polarization state.

Pancake optics work by reflecting light back and forth within the optical system. To reflect the light correctly and avoid image artifacts, the polarization state of light must be precisely controlled. Unfortunately, plastic materials usually have large birefringence that disturbs the polarization state, and until now all-plastic lenses have not been able to overcome the disturbance of the polarization state.

Kopin® Corporation has developed an all-plastic Pancake® optics for virtual reality (VR), augmented reality (AR) and mixed reality (MR) applications. This is a major advance and believed to be the first all-plastic Pancake optics with excellent performance. Pancake optics, compared to other optics designs, can provide a far superior magnified image quality in a much thinner form factor, especially for products with field of views (FOV) ranging from 50 degrees to 100 degrees. However, previous Pancake optics needed at least one spherical glass lens to avoid image artifacts caused by birefringence of the plastic material, but this glass lens added both weight and cost to the lens system. Kopin’s new all-plastic Pancake optics with all aspherical lenses, substantially reduces the weight and thickness while significantly improving the image quality – all at a lower cost. Pancake optics work by reflecting light back and forth within the optical system. To reflect the light correctly and avoid image artifacts, the polarization state of light must be precisely controlled. Unfortunately, plastic materials usually have large birefringence that disturbs the polarization state, and until now all-plastic lenses have not been able to overcome the disturbance of the polarization state.

Pancake optics work by reflecting light back and forth within the optical system. To reflect the light correctly and avoid image artifacts, the polarization state of light must be precisely controlled. Unfortunately, plastic materials usually have large birefringence that disturbs the polarization state, and until now all-plastic lenses have not been able to overcome the disturbance of the polarization state.

Kopin’s all-plastic two-element Pancake optics have virtually no birefringence. At the core of the technology is a patented aspherical optical lens design that achieves great image performance, while preserving the negligible birefringence of a special plastic material with unique characteristics. Kopin’s first all-plastic Pancake optics (named P95) optimized for Kopin’s 1.3” 2.6K x 2.6K organic light emitting diode (OLED) micro display (2560 x 2560 resolution) provides a 95° field of view. The center holds an extremely sharp image with excellent modular transfer function. This sharpness is maintained even at the edges of the field of view, a critical and difficult to achieve performance feature for VR applications. At just 16mm thickness and only 15g per lens set, the new Pancake optics are dramatically thinner and lighter than the optics used in today’s VR headsets and provides exactly what consumers have been asking for. Combined with Kopin’s 2.6K x 2.6K high-brightness OLED micro display, the P95 pancake optics provide a virtual image equivalent to a 250-inch diagonal display viewed at 10-foot distance with excellent image performance for VR applications. CEO, John Fan said “The challenge of finding a suitable plastic material with the required optical properties has been solved, as Pancake optics are perfect for VR headsets. Our first design, P95, is specifically optimized for use with our 2.6K x 2.6K OLED high-brightness micro displays. This new technology would be ideal for VR, but we believe this unique optics would also be useful for MR and AR applications. With all-plastic Pancake optics and duo-stack OLED micro displays, the dream of stylish, super lightweight (< 100 g), compact VR/MR/AR high performance headset products is finally reachable. We plan on offering our new optics as either a stand-alone component or in a module with our OLED micro displays. We are delighted that we already have the first design-in partner for our P95 optics.”

Birefringence is an optical property in certain materials, like polymers, whereby the speed of light in the material is different for the opposite polarization orientations, such that the polarization state of light is altered after passing through birefringent materials. In most optical systems, the polarization state of light does not affect the image formation, which explains why polymers, which are light and can make aspherical lenses at low cost, are used in many applications. However, conventional polymers cannot be used in Pancake optics, which is sensitive to polarization disturbance.

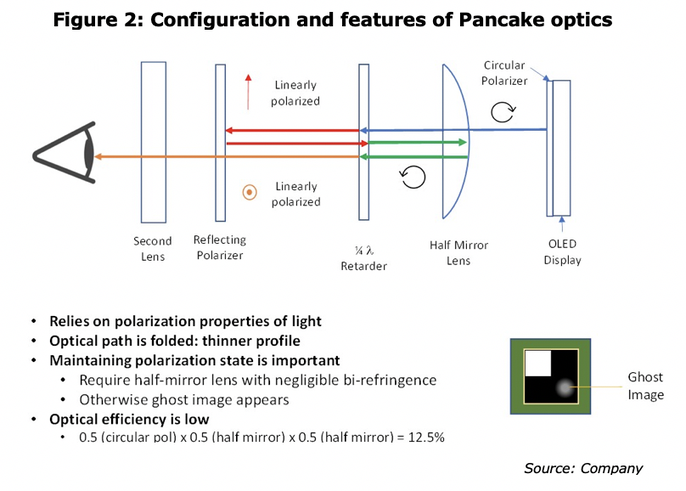

The next figure shows the configuration of the Pancake optical design and how polarization is used to fold the optical path to thin the design. Circularly polarized light from the OLED display passes through the first lens with half reflection/transmission coating (half-mirror lens). After passing through a quarter wavelength (1/4 lambda) retarder, the light becomes linearly polarized and is reflected by the reflecting polarizer. After passing through the 1/4 lambda retarder, reflected by the half mirror lens, and passing through the 1/4 lambda retarder again, the light is linearly polarized but 90° rotated from the first pass and goes through the reflecting polarizer.

Birefringence is an optical property in certain materials, like polymers, whereby the speed of light in the material is different for the opposite polarization orientations, such that the polarization state of light is altered after passing through birefringent materials. In most optical systems, the polarization state of light does not affect the image formation, which explains why polymers, which are light and can make aspherical lenses at low cost, are used in many applications. However, conventional polymers cannot be used in Pancake optics, which is sensitive to polarization disturbance.

The next figure shows the configuration of the Pancake optical design and how polarization is used to fold the optical path to thin the design. Circularly polarized light from the OLED display passes through the first lens with half reflection/transmission coating (half-mirror lens). After passing through a quarter wavelength (1/4 lambda) retarder, the light becomes linearly polarized and is reflected by the reflecting polarizer. After passing through the 1/4 lambda retarder, reflected by the half mirror lens, and passing through the 1/4 lambda retarder again, the light is linearly polarized but 90° rotated from the first pass and goes through the reflecting polarizer.

The pancake optics are a natural fit for a VR headset with micro OLED displays. and can be used for a mixed reality headset where a video see-through capability is used. However, the light loss is too great for an optical see-through design, unless the micro-OLED display brightness is significantly increased, or micro-LED displays are used.

|

Contact Us

|

Barry Young

|