Vertical Divider

|

JOLED Ships Printed OLED Monitors – A significant Development

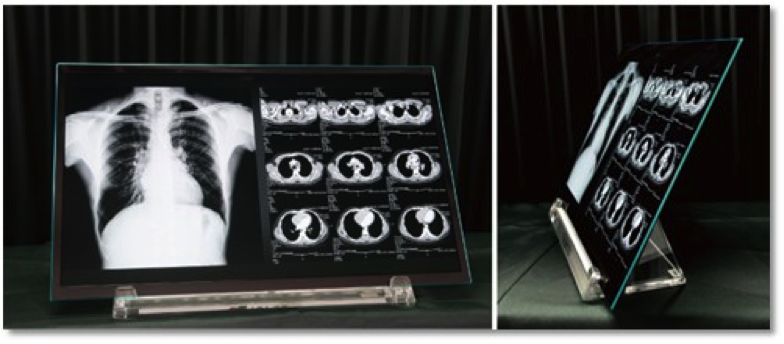

December 11, 2017 In May we reported that JOLED was using polymer material from Sumitomo on its ink-jet printing line (from Panasonic) to ship samples of 21” monitors to Sony for evaluation with expectations that actual shipments of commercial products would begin in 2018. JOLED announced that it had begun such shipments, which would make the first time that panels produced on an ink-jet printing platform have moved into commercial production. Kateeva, a California based manufacturer of ink-jet printing systems announced the release of two ink-jet printing tools for R&D and pilot line OLED production, but JOLED’s commercial production, regardless of how small the unit volume might be, raises the bar for OLED manufacturing. JOLED is producing 21.6” 4K resolution panels that will be used in the medical space due to OLED technology’s ability to produce high contrast images. The display is shown to be a black and white panel, which has a 204 ppi that is equivalent to 68 ppi, if it were full color. Imaging systems are only as good as their output and if the images they produce cannot be effectively displayed than the purpose of such imaging is lost. In the case of OLED, the contrast, which is the difference between the darkest black and the whitest white, is almost infinite, far in excess of LCD displays, which have an average contrast ratio of between 1000:1 and 4000:1. This allows medical or surgical staff to see detail that might be lost using standard LCD monitors and can be key to positive patient outcomes. The displays are expensive and range from under $1,000 to over $20,000, which makes them ideal for early stage ink-jet production, which will initially carry higher production costs than other methodology. Given the use of a Gen4.5 fab and relatively low volume, it is unreasonable to compare costs with 6th Gen VTE fabs. Figure 1: JOLED Medical Display Demo Source: JOLED

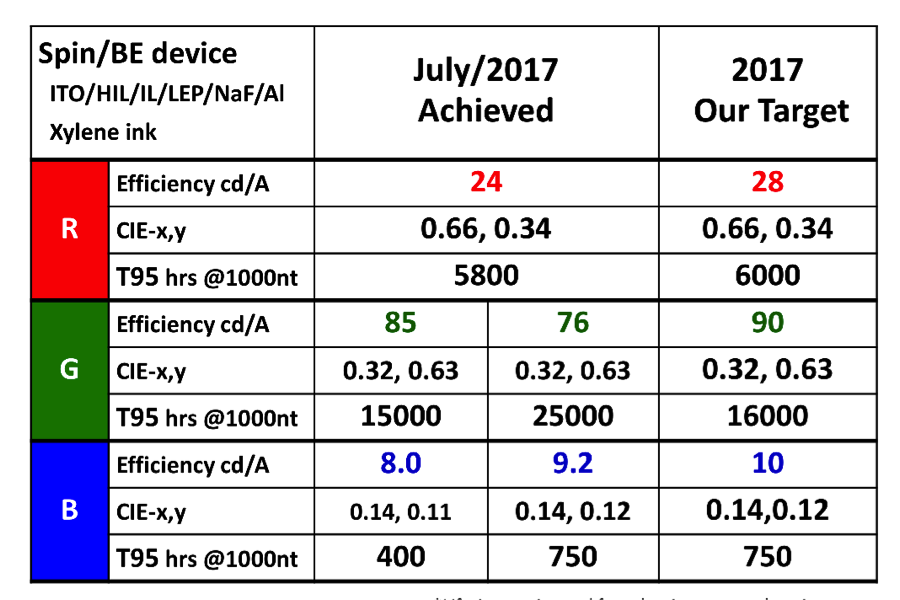

JOLED claims that the printing method is 20 percent to 30 percent cheaper than the current evaporation process. Yoneharu Takubo, JOLED’s technology chief, said at a news briefing, “We eventually want to make the printing method a de facto standard” for producing OLED panels. At the briefing, Takubo confirmed that JOLED, created in 2015 by merging the OLED divisions of Sony and Panasonic Corp is seeking to raise 100 billion yen ($888 million) by the end of this financial year to expand production capacity. Takubo said JOLED is in talks with several global panel producers for licensing the new production technology to make television panels. He didn’t specify the names of the panel makers. At the recent OLED Summit, Sumitomo showed the results of their latest material performance. Figure 2: Sumitomo’s Polymer Performance Source: Sumitomo Chemical

|

|

|

Contact Us

|

Barry Young

|