Vertical Divider

|

JBD Attacks Problem of Integrating Micro LEDs with Silicon Substrates

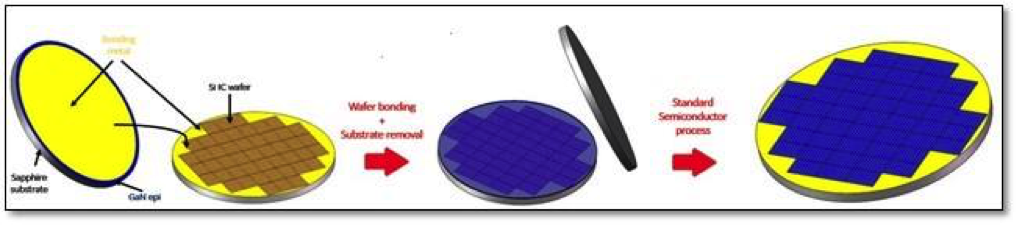

March 12, 2018 One of the more obvious applications for Micro LEDs is micro displays and Hong Kong based JBD a 2015 start-up funded by a $10m investment from the Beijing Beida Jade Bird Group have bypassed the current flip-chip technology and have moved to a monolithic production process that alleviates many of the issues facing micro-LEDs. Rather than create the drivers and LEDs as separate devices that need to be connected, JBD has developed a process that bonds a blank sapphire wafer coated with GaN (Gallium Nitride) to the silicon driver wafer, and then removes the sapphire substrate leaving the GaN material on top of a Si substrate, similar to LCoS and OLED micro displays. There is no alignment issue between the two wafers and no thermal issue after removing the sapphire substrate, the company claims to have solved two of the big issues surrounding the commercialization of micro-LEDs for micro displays and as the LEDs are produced directly on the driver circuitry matrix, they can achieve pixels as small as a few microns on such a monolithic device. Figure 1: Monolithic Micro-LED Process Source: JBD

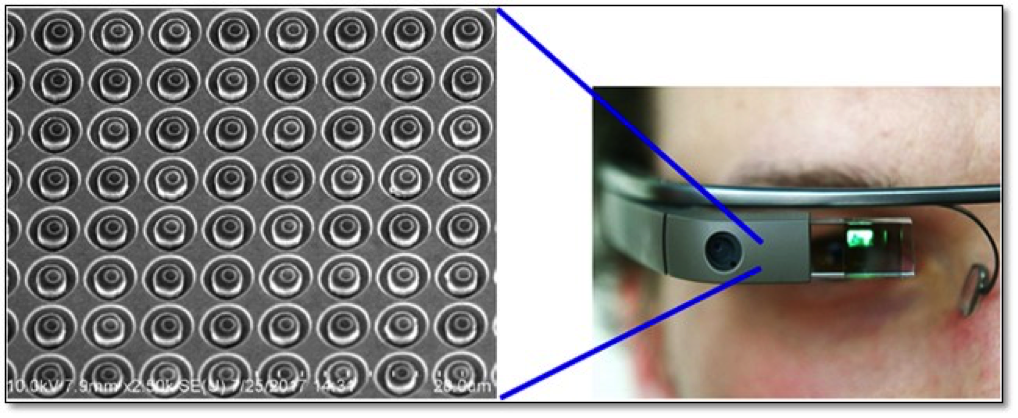

The company has only been able to build a micro display with VGA resolution. They will have to increase the resolution to 2K by 2K to have a place in the VR/AR market. Figure 2: Micro-LED display w.5um pixel pitch Source: JBD

|

|

|

Contact Us

|

Barry Young

|