Vertical Divider

Foldable Display Makers Considering Replacing Polarizer w/Color Filter

July 19, 2020

On the other hand, other approaches to reducing the thickness of foldable OLEDs seemed to have a low probability of success. An attempt to replace the two layers of polyimide (PI) substrate under the foldable OLED into a single layer is typical. "A single PI substrate is not easy to handle, and it is highly likely to damage the substrate in the LLO (Laser Lift Off) process," UBI Research said. LLO refers to a process of separating a PI substrate from a carrier glass using a laser in a flexible OLED substrate process.

There is also a method of reducing the thickness of inorganic and organic materials used in thin film bags (TFEs) that protect OLEDs from moisture and oxygen. Currently, the thickness of inorganic and organic materials is 1 µm and 4 to 8 µm, respectively. A study to reduce the thickness of organic materials by increasing the flexibility of the OLED panel is a ubiquitous analysis that the signal-to-noise ratio (SNR) of the touch sensor is high due to the signal of the thin film transistor (TFT) that acts as a switch in the display, making it difficult to apply.

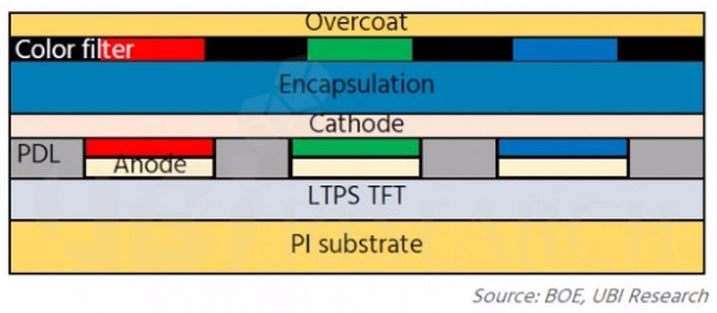

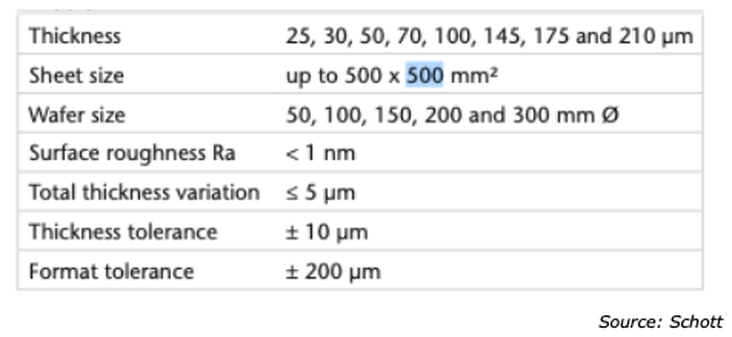

UBI Research, reports that BOE is planning to replace circular polarizers with color filters in their foldable displays with the expectation that the displays will be thinner and brighter. The foldable OLED stacks a touch-integrated electrode (such as Samsung Display's Y-octa, a polarizing plate, an optical adhesive (OCA), and a cover window in turn on the OLED emitting layer. The cover window uses a hard-coated transparent polyimide (PI) film or ultra-thin glass (UTG). UBI claims that even as 100um polarizers are being replaced by 10um films they are still considered too thick and tend to lower the overall brightness of the OLED panel more than a color filter does. BOE, which has had low yields for its foldable OLEDs, showed a 5.46 inch WQHD foldable OLED panel in 2017 that utilized color filter instead of a polarizer. The company said that it was “110 µm thinner and allowed 23% more light thru than OLED panels using polarizers.” They didn’t identify what material was used but it isn’t UTG, which currently has a minimum thickness of 25µm and wasn’t available in 2017.

There were also reports that Samsung, the main provider of foldable OLEDs is considering the same change.

Figure 1: BOE Color Filter on OLED Smartphone Panel

July 19, 2020

On the other hand, other approaches to reducing the thickness of foldable OLEDs seemed to have a low probability of success. An attempt to replace the two layers of polyimide (PI) substrate under the foldable OLED into a single layer is typical. "A single PI substrate is not easy to handle, and it is highly likely to damage the substrate in the LLO (Laser Lift Off) process," UBI Research said. LLO refers to a process of separating a PI substrate from a carrier glass using a laser in a flexible OLED substrate process.

There is also a method of reducing the thickness of inorganic and organic materials used in thin film bags (TFEs) that protect OLEDs from moisture and oxygen. Currently, the thickness of inorganic and organic materials is 1 µm and 4 to 8 µm, respectively. A study to reduce the thickness of organic materials by increasing the flexibility of the OLED panel is a ubiquitous analysis that the signal-to-noise ratio (SNR) of the touch sensor is high due to the signal of the thin film transistor (TFT) that acts as a switch in the display, making it difficult to apply.

UBI Research, reports that BOE is planning to replace circular polarizers with color filters in their foldable displays with the expectation that the displays will be thinner and brighter. The foldable OLED stacks a touch-integrated electrode (such as Samsung Display's Y-octa, a polarizing plate, an optical adhesive (OCA), and a cover window in turn on the OLED emitting layer. The cover window uses a hard-coated transparent polyimide (PI) film or ultra-thin glass (UTG). UBI claims that even as 100um polarizers are being replaced by 10um films they are still considered too thick and tend to lower the overall brightness of the OLED panel more than a color filter does. BOE, which has had low yields for its foldable OLEDs, showed a 5.46 inch WQHD foldable OLED panel in 2017 that utilized color filter instead of a polarizer. The company said that it was “110 µm thinner and allowed 23% more light thru than OLED panels using polarizers.” They didn’t identify what material was used but it isn’t UTG, which currently has a minimum thickness of 25µm and wasn’t available in 2017.

There were also reports that Samsung, the main provider of foldable OLEDs is considering the same change.

Figure 1: BOE Color Filter on OLED Smartphone Panel

Figure 2: Schott’s UTG Specs and Geometric Tolerances

|

Contact Us

|

Barry Young

|