|

Aixtron Moves Closer to a Commercial OLED Deposition System

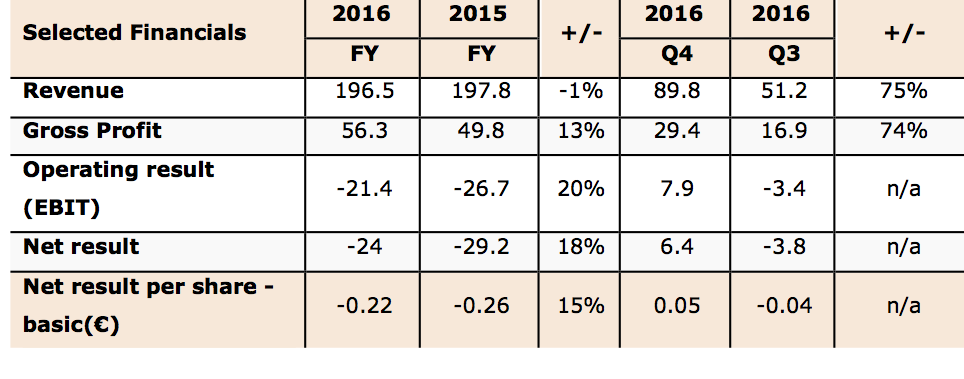

April 17, 2017 Aixtron announced it has partnered with a major OLED display manufacturer to provide an OLED deposition system that will be used to qualify and develop the tool for commercial production. The tool, which is based on Aixtron’s OVPD (Organic Vapor Phase Deposition) system differs from traditional OLED deposition systems that use VTE (Vacuum Thermal Evaporation) to deposit organic film structures for OLED displays in that it mixes the organics with a hot inert gas, and a close-coupled showerhead to reduce the extraneous organic material that builds up in the reaction chamber during the VTE process. This material, which has to be removed periodically, can flake off and become a contaminant, and wastes a very significant amount of organic material. The OVPD system is said to increase the material usage efficiency significantly. The Aixtron tool being jointly developed is larger than the Gen 1 beta tool (300mm x 400mm) that the company has previously mentioned, and is one step above a ‘proof of concept’ platform. Aixtron will still have to make significant investments to bring the tool to a commercialization stage, but any process that can increase the utilization efficiency of small or large panel OLED production would be of interest to OLED panel producers. Aixtron has invested heavily in the OLED deposition tools but has been usurped by Canon’s Tokki. Perhaps, this is an opportunity for Aixtron to recover as its prime revenue source, MOCVD tools for LED production have been underachieving of late. Aixtron reported 2016 revenue of 196.5m EUR, basically flat to 2015. As of December 31, 2016, the equipment order backlog totaled EUR 78.1m, a 67% increase vs. EUR 46.7m at the beginning of the year. Gross Profit, Net Profit and Earning per share all inproved in 2016, vs. 2015 as operating costs came down. Table 5: Selected Aixtron Financials (Euro m) Source: Company

Source: Garmin

|

Vertical Divider

|

|

Contact Us

|

Barry Young

|