Vertical Divider

μLEDs Require Complex Driving Circuits

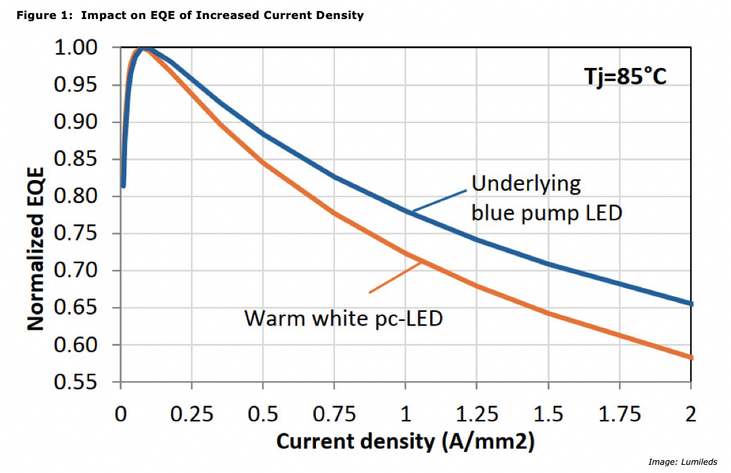

With μLEDs needing to get to under 3μm x 3μm to reach competitive cost ranges, maintaining efficiency is a big challenge as the small dies suffer from all sorts of non-radiative side-wall effects and as they get smaller the peak current density they need to operate without droop and color shift increases. The accuracy of how that peak current is delivered is also very important as otherwise the efficiency moves away from peak, and the color may shift.

With μLEDs needing to get to under 3μm x 3μm to reach competitive cost ranges, maintaining efficiency is a big challenge as the small dies suffer from all sorts of non-radiative side-wall effects and as they get smaller the peak current density they need to operate without droop and color shift increases. The accuracy of how that peak current is delivered is also very important as otherwise the efficiency moves away from peak, and the color may shift.

CMOS LTPS has been used in nearly all demonstrators as the backplane of choice, due to the high current capability of CMOS LTPS and the high speed switching capability. There is still much discussion on how best to drive a MicroLED display, but PWM (Pulse Width Modulation or time-based dithering) schemes with very short pulses down to the ns regime in length are needed to achieve good grey-scales. The uniformity of the current driven is important to allow for the TFT level computing to generate grey scale using PWM. The use of CMOS LTPS in the TV market (as indeed large TVs such as “The Wall”) seems like a contradiction: why would anyone want to use LTPS in a large panel? Over time if the stability and mobility of oxide can be increased and the peak current capacity, then large panels can adopt IGZO as the active-matrix backplane technology.

At DisplayWeek 2020 papers were focused on demonstrating the core technology and used a simple 2T1C circuit. In 2021 most papers use more complex compensation circuits as developers decide what driving approach and how much compensation is actually needed to get MicroLED to deliver high brightness, color controlled, high grey-scale images.

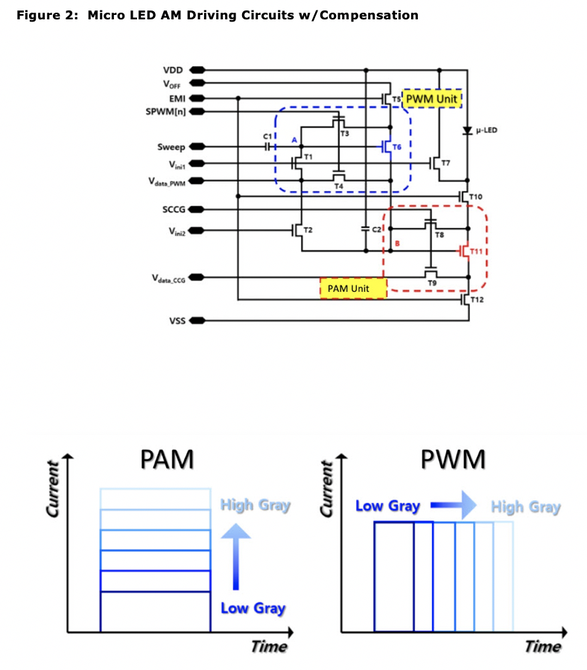

The industry seems to have moved down the path of multi-transistor compensated circuits as part of a PWM approach to TFT-driven MicroLED driving. One example of this was presented by Samsung and Sungkyunkwan University at DisplayWeek 2020. Their paper, as well as a follow up paper from DisplayWeek 2021, demonstrate 9T3C and 12T2C circuits (see first figure for example of 12T2C circuit) capable of Pulse Amplitude Modulation (PAM) and Pulse Width Modulation (PWM) for driving the MicroLED (see second figure for an example of PAM vs. PWM as shown in the referenced papers). This circuit at the complex end of the scale where both amplitude (and hence constant current) and pulse width are both independently controllable. In the coming years, experiments between the two extremes, to achieve the goal of controllable (fixed, stable amplitude) high current, very fast pulses are likely.

At DisplayWeek 2020 papers were focused on demonstrating the core technology and used a simple 2T1C circuit. In 2021 most papers use more complex compensation circuits as developers decide what driving approach and how much compensation is actually needed to get MicroLED to deliver high brightness, color controlled, high grey-scale images.

The industry seems to have moved down the path of multi-transistor compensated circuits as part of a PWM approach to TFT-driven MicroLED driving. One example of this was presented by Samsung and Sungkyunkwan University at DisplayWeek 2020. Their paper, as well as a follow up paper from DisplayWeek 2021, demonstrate 9T3C and 12T2C circuits (see first figure for example of 12T2C circuit) capable of Pulse Amplitude Modulation (PAM) and Pulse Width Modulation (PWM) for driving the MicroLED (see second figure for an example of PAM vs. PWM as shown in the referenced papers). This circuit at the complex end of the scale where both amplitude (and hence constant current) and pulse width are both independently controllable. In the coming years, experiments between the two extremes, to achieve the goal of controllable (fixed, stable amplitude) high current, very fast pulses are likely.

Figures adapted from Y.-H. Hong, E. K. Jung, S. Hong, and Y.-S. Kim, “61‐2: A Novel Micro‐LED Pixel Circuit Using n‐type LTPS TFT with Pulse Width Modulation Driving,” SID Symposium Digest of Technical Papers, vol. 52, no. 1, pp. 868–871, May 2021, doi: 10.1002/sdtp.14822.

The requirements of MicroLED driving are found from fast switching transistors or diodes, with high current draw capability due to decent mobility. Amorphyx, has two TFT alternative solutions that get to these requirements - the AMeTFT high mobility oxide transistor and their very fast switching AMNR approach. The aim overall is to use diodes and higher performance transistors to reduce the complexity of the overall design down from this 12T2C type levels.

Original Content by Ian Hendy via Display Daily

The requirements of MicroLED driving are found from fast switching transistors or diodes, with high current draw capability due to decent mobility. Amorphyx, has two TFT alternative solutions that get to these requirements - the AMeTFT high mobility oxide transistor and their very fast switching AMNR approach. The aim overall is to use diodes and higher performance transistors to reduce the complexity of the overall design down from this 12T2C type levels.

- Their first circuit, the 211 circuit (and concept overall) uses two AMNR voltage controllers plus a very stable, high current, high mobility oxide transistor, may be able to provide accurate current densities and at short pulse times without the need much more complex circuits.

- The AMNR voltage divider can be used explicitly for some of the Vth compensation and the fast oxide AMeTFT (Amorphous metal) transistor with high stability and mobility can enable shorter pulses.

Original Content by Ian Hendy via Display Daily

|

Contact Us

|

Barry Young

|